|

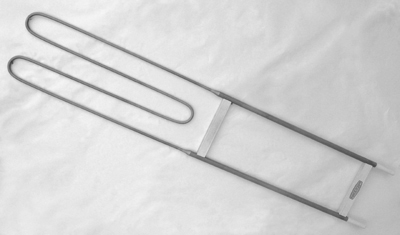

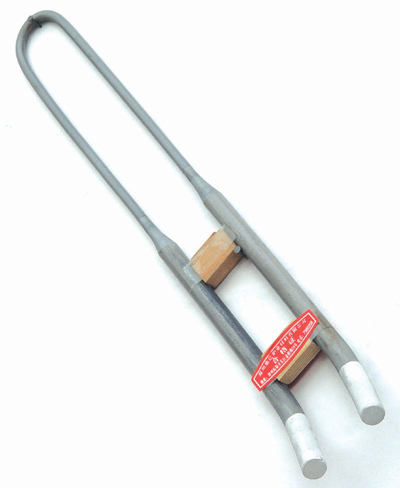

U type

mosi2 heater,mosi2

heating elements is the most commonly used

design. The heating zone is welded to terminals that are typically twice

the diameter of the heating zone. U MoSi2 heating elements are

manufactured to industry-standard resistance values. The same spacing,

power ratings, and voltages can be used as with other molybdenum

disilicide elements. |

|

w type

1700°C

mosi2 heater, mosi2 heating

elements

|

|

W type mosi2 heater,mosi2

heating elements are ideal for furnaces with low

chamber height, offering longer hot zones that require fewer elements to achieve

the desired temperature. This results in reduced energy loss at the cold ends,

making them more cost-effective than U type molybdenum disilicide heating

elements. |

|

L

type

(90° Bent)

1700°C

mosi2 heater, mosi2 heating

elements

|

|

L type (90° Bent)

mosi2 heater,mosi2 heating elements are designed

for furnaces where electrical connections above the roof are not feasible.

Unlike standard elements, the hot zone(or the cold ends) of these elements can

be bent at a 90° angle,allowing for efficient multi-row installation on furnace

walls. This enables precise power control at different levels while optimizing

space within the furnace. |

|

arc

type(45° bent)

1700°C

mosi2 heater, mosi2

heating elements

|

|